Services:

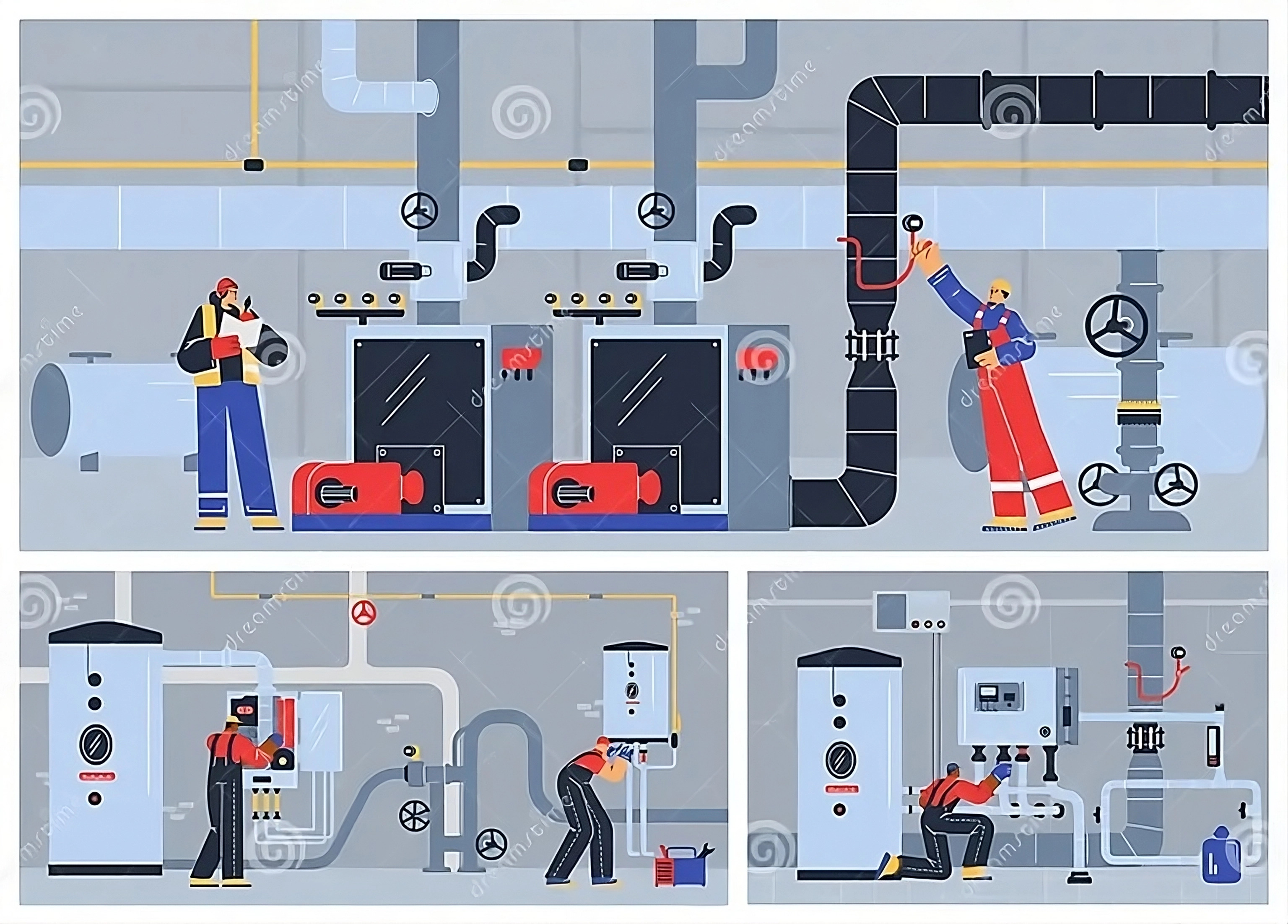

Maintenance and Repair:

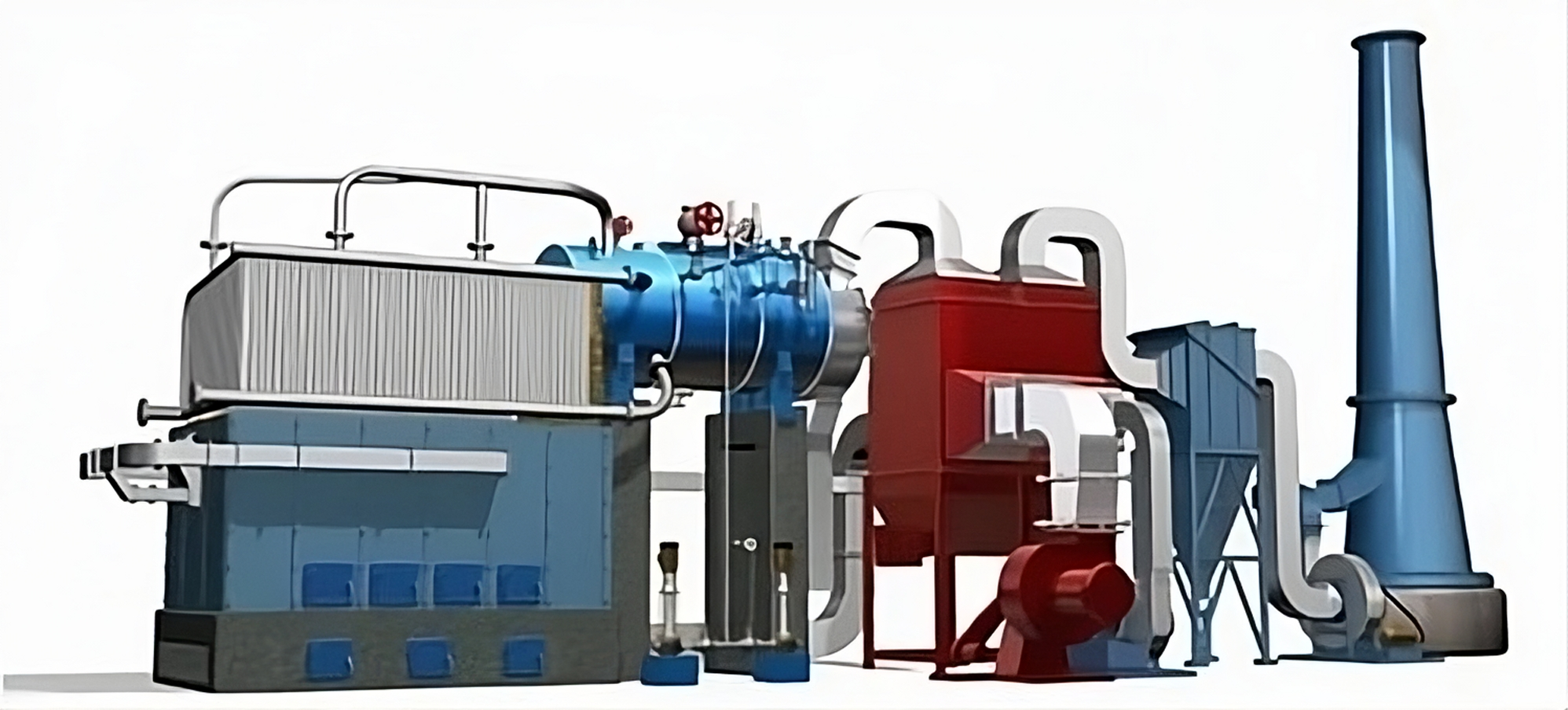

Boilers need proper maintenance to avoid various problems such as:

➢Unexpected system shutdown due to undetected issues

➢Decreased work and production safety

➢Lowered system efficiency and higher operating cost

➢Shortened equipment and system lifespan

➢Increased maintenance and repair costs when problems arise

THERMO FAB ENGINEERS REPAIR AND MAINTENANCE SERVICE :

Thermo Fab Engineers offers comprehensive boiler maintenance and repair services. These services are available both on a periodic schedule and on a call-out basis to meet your specific needs. We are committed to providing high-quality workmanship, timely service, and long-term warranties for your peace of mind. Thermo fab engineer professional and experienced technical staff in the boiler industry, are always ready to consult, survey and evaluate your boiler needs We are committed to offering the most optimal solutions for your business. Thermo fab engineers offers a comprehensive range of repair and maintenance services.

Here are the key points outlining their offerings:

1. Boiler and Pressure Vessel Repairs:

2. Heat Exchanger Maintenance:

3. Pipeline Services:

4. Fabrication and Welding:

5. Preventive Maintenance Programs:

6. Emergency Repair Services:

7. Technical Support and Consulting:

8. On-Site and Off-Site Services:

WHAT MARTECH BOILER'S SERVICE CAN DO FOR YOU?

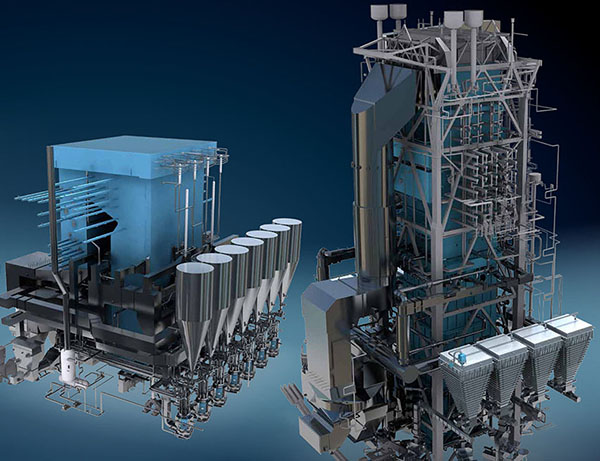

BOOST CAPACITY-ENHANCE PERFORMANCE

ADAPT TOPOLICIES AND TRENDSIN THEWORLS

LOWERRISK OFINCIDENTS AND INCREASE PRODUCTION

CHANCE TO SWITCH TO ADVANCED TECHNOLOGY, SAVETIMEAND OPERATING COSTS